Brake Systems

- Brake/Shift Levers

- Caliper Brakes (Road)

- Cantilever Brakes (MTB)

- Brake Levers

- Brake Shifter Combination Levers

- Brake Boosters

- Brake Cables

- Brake Carriers

- Brake Hangers

- Brake Pads

- Titanium Brake Hardware

Computers

Cranks and Chainrings

Forks

Frames & Framesets

Freewheels and Cassettes

Front Derailleurs

Grips

Handlebars

Handlebar Extensions

Headsets

Helmets

Hubs and Skewers

Lubricants

Metal Guide - Bicycle Metallurgy

Mirrors

Pedals and Toe Clips

Pumps and Inflation Systems

Racks

Rear Derailleurs

Rims & Rimstrips

Saddles

Seatposts and Binder Bolts

SRP Replacement Titanium &

Aluminum parts - Master Index

Stems

Tires

Tubes

Shoes

Spokes (Tables Only)

Tools - Bicycle Repair Tools

Yakima Fit List -to fit all cars

Notes

Links

Home

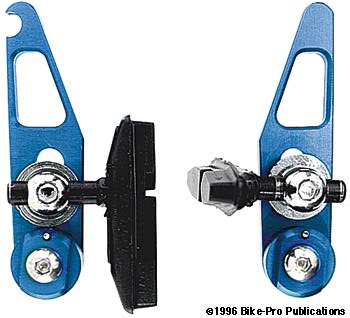

Crystal Design Power Brake - Cantilever Brake

The Crystal brake was introduced in late 1993.

Mechanical explanation of Power Brake. It is machined from billet aluminum to make a 9.07mm thick arm that is 87mm tall. The base the arm is 20.3mm wide, this dimension enlarges to 22mm at 46mm from the bottom of the arm. The upper 41mm section of the arm narrows to 9mm at the top. An 8.3mm by 17.7mm slot is milled in the lower arm section for the pad holder parts to pass through and adjust within. The rear of the lower arm section is separately milled to reduce the wall thickness to 6.38mm in an area 17.4mm wide and 27.2mm tall. This rear milling reduces weight and makes a defined seat for a rear angle adjustment washer. A much larger area is milled out of the upper arm section, leaving just a 2mm and 2.5mm thick by 9mm deep wall extending up to the straddle cable. A fiber bushing impregnated with brass and lubricating properties is passes through the base for the arm to swivel around the mounting stud. There are two small holes used to anchor one end of the tension spring. One is below the bushing, the other to the inner side. Both internal tension springs are adjustable, and replaceable. A machined aluminum cap covers the spring, with a small hole through the top for other spring end to anchor in. A hole drilled through the center allows the mounting bolt to tighten through the cap. Two cuts are made across the top of the cap for a 13mm wrench to grip. With the proper tension on the spring the mounting bolts are tightened to hold the tension while still allowing the arm to rotate smoothly.

Russ Crystal has chosen to use a four piece pad holding system. Now, this part is a little tricky. Notice the price that we sell this brake for. The reason for this low price is that unlike almost everyone else who sells a machined cantilever after-market brake, Russ Crystal owns his own machine tools to make his own parts. But Russ owns milling centers and doesn't have a turning center so in the case of bolts and nuts to keep the cost of his way down he buys an off-the-shelf solution. He uses the same imported modest to poor quality pad holding eyebolt used in number of other brakes because buying and using the SRP Titanium model would add at least $6 to cost of the brake. We recommend that some of the money saved in buying this brake be used to buy the SRP Titanium replacement at the same time. Although all 3 of the SRP pad holders will work we found the short shank, bulb shape (our part # 06-91-PH) to be the best choice. Each of the two steel originals weigh 9 grams, the Ti replacement weigh 4.5 grams and is of a much, much higher quality. The pad holding base washer behind the pad holder is made of steel with a wedge shaped thickness. This steel piece weighs 4 grams and Russ feels that use of an aluminum one in its place would deform the surface under tightening pressure, leaving ridges so the pad may not be able to adjust freely in the future.

At the back of the arm is a machined aluminum washer with a flat back facing the brake arm and a convex surface on the other side. The final piece is a steel tightening nut. Threaded to 6mm by 1mm, with a 4.8mm thickness, a 2 grams weight, and having an outer hex shape to be gripped by a 10mm socket or open ended wrench. This nut can be replaced with an SRP Ti version (our part # 06-91-010) cutting the weight of each to 1 gram. The Crystal Power Brake comes with a 300mm long Dia-Compe straddle cable. It has a lead anchor at one end with a separate lead finger grip for quick release purposes. The lead anchor fits into the top of the left arm. The right arm has a downward diagonal hole drilled through the top. Another hole drilled from the top, tapped with threads is for a set screw to turn in. The straddle cable passes from the upper inside to the lower outside, when the proper length and position are determined, the upper set screw is tightened to hold the straddle cable in place. End of Mechanical.

Crystal includes a Dia-Compe cable carrier with the Power Brake. Using a stamped aluminum hanger plate, the carrier uses a keyed steel bolt with a hole through it, two steel washers and a steel nut to clamp onto the brake inner wire once it passes through the hole in the bolt. Each Power Brake comes with Kool-Stop Eagle Claw 2's in Black. The non-thread mounting post is made of aluminum giving the pair of pads a weight of 41 grams per pair.

The brake comes with two stainless steel mounting bolts. The 6mm by 1mm bolts have a 12mm length, 4mm hex fitting and a 3 gram weight each. We found the Power Brake to have a Bike-Pro brake profile measurement of 29mm. The Power Brake can be used on the front or rear. The weight of the Power Brake is 145 grams. To this add 6 grams for the mounting bolts and 11 grams for the cable carrier for a total weight of 162 grams. The brake arms and caps are anodized Blue, Black. Lavender, or Silver.

Color-B-BK-L-S $ Price in Catalog