The plant that was under contract to manufacture the Bontrager rims had an explosion ripping apart the building and killing 2 of the workers. While the facility has been reconstructed, there have been huge delays in Bontrgaer rim deliveries. Though they have been used by bicycle makers, the Bontrager rims haven't been a very big success with cyclists for after market replacements.

The BCX-1 is one of two rims designed by the Bontrager organization, and manufactured by Weinmann in Olney, Illinois. You may remember that Keith Bontrager's first entry into the rim work was the cutting, re-rolling and joining of Mavic MA-40 rims to make it accommodate 26" mountain tires several years ago when light, high performance mountain rims were un-heard of. His recent thoughts on rims are brought to bear in the BCX rims. The BCX rims are extruded of an aluminum alloy, whose composition they won't reveal. Also unrevealed is whether or not the rim is tempered or treated to any additional hardness through either cooling or solution heat treating. But it is said that the aluminum used was chosen based on its intrinsic strength for rim purposes first, rather than its ability be easily worked or manufactured with.

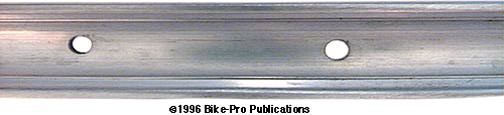

The BCX-1 extrusion uses single wall, channeled construction to form a box shape. The sidewalls are flat, moving upward at a straight vertical. The channels, in the extrusion, rather than being round, as is customary, are made using right angled triangles. Both channels position the right angle where the sidewall and hub facing wall join, adding some lateral stiffness to the rim. The BXC-1 uses a thicker 2.8mm spoke bed rather steel eyelets to equalized spoke nipple stress and prevent nipple pull through failure. The extrusion, once rolled has the ends joined using triangular aluminum pins that conform roughly to the shape of the channel with space for a bonding agent making the joint permanently secure.

Once the rim ends are joined, the entire rim is given "brushed" finish. The spinning steel brush bristles leave fine lines in the direction travel on the rims three outer surfaces. Bontrager has settled on this brush finish because it leaves the surface with a fine texture that the brake pads adhere to producing a better braking surface. The brushed finish also tends to take down any high spots at the pinned joint trying to deliver a continuous smooth surface for brake pad contact. Though admirable, the joints on some of the rims we inspected, still had very small flaws in the brake contact surface at the joint, which would probably not be noticed in use.

The BCX-1 is made in a raw brushed natural Silver color. Because it remains un-anodized the Silver rim will have greater heat dissipation during braking. Both anodizing and especially heat treating reduce aluminum's thermal conductivity. The BCX-1 is sold with the suggestion by Bontrager that it be used as a front wheel rim. We sell it with either 28 or 32 spoke holes and drilled for a Presta valve. For more specifics please refer to the Rim table. We noticed the irregularities in the weight to hole drilling relationship and double checked our weights, which were accurate. This relationship variation may be a product of extrusion wall thickness deviation.

BCX1 26" (Hole-32-36 / S) $ Price in Catalog

Bontrager also has Weinmann produce for them, a suggested rear wheel use rim which they call the BCX-2. The basic shape and design of the BCX-2 isn't very different from the BCX-1. The BCX-2 has ever so slightly thicker sidewall extrusions, the bead hook is larger in diameter, the thickness of the spoke bed has been raised from 2.8mm to 3.3mm and there are two small ridges on the upper surface of the cross-tie wall.

The alloy used is the same as the BCX-1, as is the joint fastening technique, and the finish for the rim. For more specifics, please to the Rim table.

26" x 32 hole(Hole32-36 / S) $ Price in Catalog

26" x 36 hole (Color-GY-S) $ Price in Catalog